Cooling system use precautions and maintenance suggestions

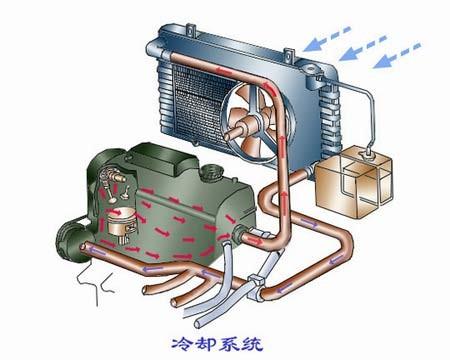

Cooling systems are an integral part of many mechanical equipment and industrial production. Its role is to reduce the temperature of the equipment to maintain its normal operation. If the cooling system is not used or maintained correctly, it can lead to equipment failure, wasted energy and even safety hazards. Therefore, the following are some precautions and maintenance recommendations for cooling systems to ensure their operation and extend their service life.

Proper installation and layout of the cooling system is critical. When selecting the installation location, ensure that the cooling system can obtain sufficient air circulation for heat dissipation. At the same time, the cooling system should be avoided in areas that are vulnerable to contamination or damage to prevent impurities such as dust and grease from entering the system and affecting its normal operation.

Regular cleaning of the cooling system is essential. Over time, dirt and deposits can accumulate inside the cooling system, which can reduce the efficiency of heat dissipation. Therefore, it is recommended to check and clean the cooling system regularly to ensure that its internal channels are unobstructed. During the cleaning process, cleaning agents and tools can be used to thoroughly remove dirt and ensure that the inside of the system is dry to prevent bacteria and mold growth.

In addition, it is also very important to check the water quality of the cooling system regularly. Impurities and chemicals in the water can adversely affect the cooling system, such as corrosion and clogging. Therefore, it is recommended to regularly test the water quality and perform water treatment as needed to keep the water quality clean and stable. In addition, the water in the cooling system should be replaced regularly to prevent water quality deterioration and bacterial growth.

In addition, the temperature and pressure of the cooling system also need to be monitored regularly. Too high or too low a temperature and pressure can cause the cooling system to malfunction or leak. Therefore, it is recommended to install temperature and pressure sensors and check their readings regularly. If an exception is found, take measures to repair or adjust it in time.

Regular maintenance of the various components of the cooling system is also necessary. This includes checking and replacing cooling fans, pumps, pipes and valves. The proper operation of these components is essential to the effectiveness of the cooling system, so their working status should be checked regularly and repaired or replaced as needed.

The use precautions and maintenance suggestions of the cooling system are crucial to the normal operation and prolonging the service life of the equipment. Proper installation, regular cleaning, testing water quality, monitoring temperature and pressure, and regular maintenance of individual components are all critical steps to ensure the operation of the cooling system. Only through the correct use and maintenance, we can give full play to the role of the cooling system to ensure the stable operation of the equipment.